This site is a source of information on Zinc-Nickel (Zn-Ni) coatings as they relate to the aerospace fastener industry.

What are Zinc-Nickel (Zn-Ni) Coatings?

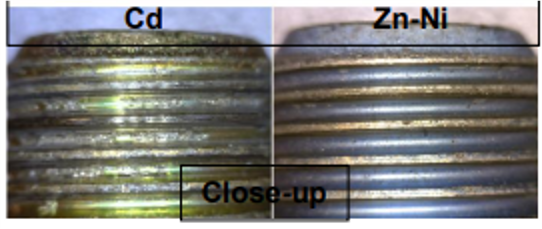

Zinc-Nickel (Zn-Ni) coatings are corrosion resistant finishes that are electroplated onto the surface of parts. They typically contain between 10-15% Nickel, and provide superior protection over zinc plating. Zn-Ni plating is common in the automotive industry, and are often REACH and RoHS complaint if hexavalent chromium is not used as a conversion coating. Zn-Ni plating without conversion or top coatings are dull grey in color.

Zn–Ni coatings often provide corrosion resistance equal to or greater than cadmium coatings and they eliminate the risk of carcinogenic exposure that creates a concern for people working with cadmium hexavalent chromium plated components[10].

History of Zn-Ni Coatings & Aerospace Fasteners

Historically fasteners used in the aerospace industry have been cadmium plated with hexavalent chromium due to its excellent corrosion resistance, low thickness, and freedom from stick-slip. Hexavalent chromium is carcinogenic[8] and is restricted under RoHS and REACH (1000 ppm)[5][6]. Suggested replacements have included trivalent chromium[4]. RoHS and REACH lists cadmium as a restricted substance (100 ppm) and known human carcinogen[5][6]. Unfortunately, cadmium plating is still commonly used in military and aerospace applications, including fasteners[9].

The military and aerospace community has been in search of an alternative to cadmium plating since the 1970s. Due to the industry's need for a stringently tested safe drop-in replacement, progress has been slow. Zinc plating has been considered as an alternative, but its performance characteristics are below cadmium plating.

In 2003, Boeing began work to develop a LHE (Low Hydrogen Embrittlement) Zn-Ni Plating as an environmental alternative to cadmium. The Zn-Ni compositions considered were from 5-15%, and brighteners and other additives were removed to make the plating porous (dull). Boeing reported positive results[2] with plans for future testing. Further testing was conducted reported in 2011 in collaboration with ES3, Boeing, and USAF. The results were highly positive, with some members stating that LHE Zn-Ni is a drop in replacement for cadmium in high strength steel landing gear components[3].

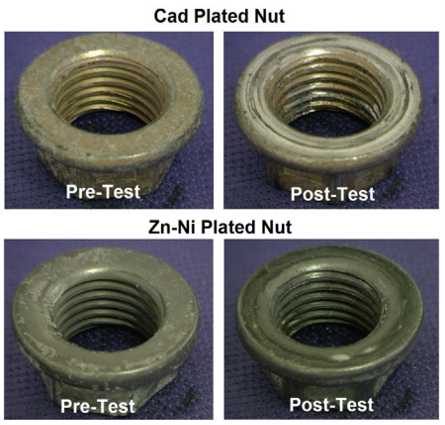

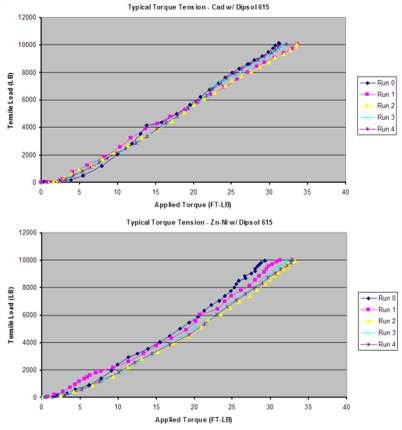

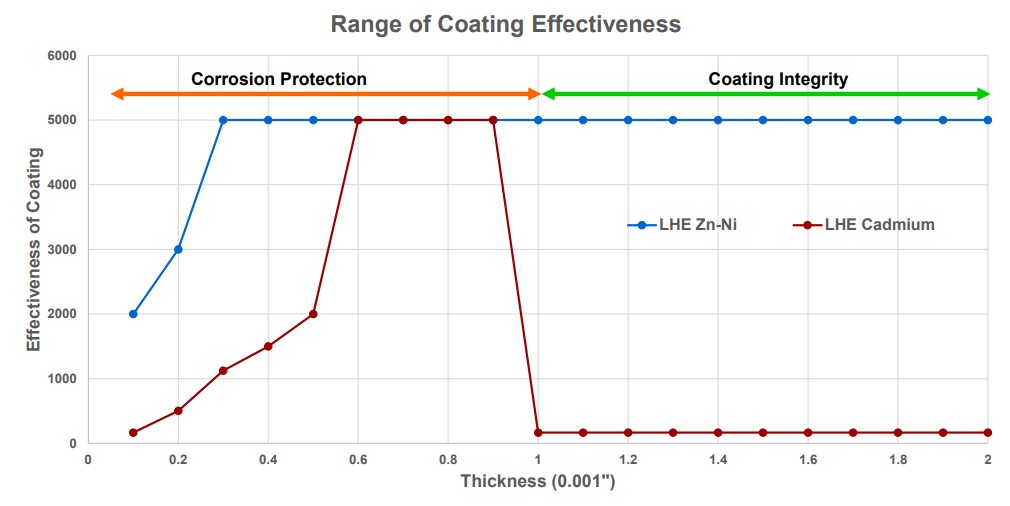

In February 2022, the Ogden Air Logistics Center (USAF) released a report titled LHE Zn-Ni Corrosion Testing and Implications for Fasteners [1]. Testing included Class 1-3 Type II plating. The following results were reported:

The report concluded that LHE Zn-Ni plating was an upgrade over cadmium hexavalent chromium plated fasteners. It recommended updating NAS (National Aerospace Standards) fastener specifications so that LHE Zn-Ni coated fasteners could be made available to the market.

LHE Zn-Ni Performance vs Cadmium

Hexavalent Chromium and Cadmium Abatement

On June 2022, Industrial Fasteners Institute (IFI) hosted a webinar on Hexavalent Chromium and Cadmium Abatement. The Defense Logistics Agency (DLA) included presentations on the transition away from Hexavalent Chromium and Cadmium plating.

Hydrogen Embrittlement and LHE Zn-Ni

Hydrogen Embrittlement (HE) causes permanent loss of ductility in a metal or alloy over a period of time and can lead to catastrophic failures. Hydrogen Embrittlement requires three conditions to occur: (1) Material Susceptibility (2) Tensile Stress (3) Hydrogen. Three conditions must be met in sufficient amount over a period of time for failure to result. For an introduction on hydrogen embrittlement failures in fasteners, please read below:

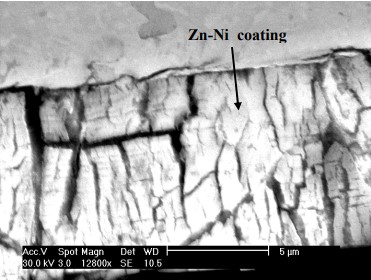

Coating processes applied to fasteners can result in internal hydrogen embrittlement. The study below examines the propensity of various plating processes to cause hydrogen embrittlement. It was found that the least embrittling process was LHE Zn-Ni, due to the permeability of LHE Zn-Ni which allowed hydrogen to escape. Testing on cyanide cadmium plating was inconclusive due to a plating process that prevented the absorption of hydrogen.

LHE Zn-Ni Plating Specifications

For aerospace fasteners:

For components:

Acid vs. Alkaline Zinc Nickel

Zn-Ni Aerospace Fasteners

November 2020 with the inception of AMS2461, The Aerospace Industries Association has decided to add the Zinc-Nickel plating option as the preferred cadmium alternative plating solution. When a part number is up for their 5-year review the NASC (National Aerospace Standards Committee) Zn-Ni Task Group will make revisions performed in accordance with the NASC Handbook and NAS380. Please note part numbers under review updated monthly.

Manufacturers of LHE Zn-Ni Aerospace Fasteners

Airfasco has begun manufacturing LHE Zn-Ni standard fasteners on the request of Aerospace OEMs. These fasteners are plated per AMS2461 and are REACH/RoHS compliant. Contact Dennis Dent (Dennis@airfasco.com) for AN bolt samples per AMS2461, Type II, Class 2, Grade A with post dip-spin Sealant Cobalt Free Plated. Airfasco has published a Zn-Ni synopsis on the advantages for transitioning to Zn-Ni plating[20].

LongLok has tested Zinc Nickel AN bolts per MIL-DTL-18240 with excellent adhesion and torque results. Contact Aaron Dollenmeyer (Aaron@LongLok.com) for AN bolts per MIL-DTL-18240 samples.

Zn-Ni Advisory Group

Sources

Comments or Questions? Please email: webmaster@zn-ni.com

This site uses cookies. By using this site you are agreeing to our privacy policy.